GX -80 ~ -10°C Industrial Refrigerators

Features of Industrial Freezers

- Microcomputer control, cascade temperature controller, digital temperature display, the regulation of unit 0.1°C, tank temperature range -150℃ ~ -10℃ adjustable.

- French Tecumseh compressor, German Bock compressor, bitzer compressor, automatic cascade refrigeration technology.

- With self-diagnosis function, freezer overload protection, high pressure switches, overload relays,thermal protection device and other security functions.

- Three sealed mold layer of insulation, Extra-thick high-density polyurethane foam insulation layer,good insulation. Inside with vacuum insulation panels.

- Large condenser design, fully guaranteed plant environment cooling effect.

- Wide volume ratio design, large load capacity design.

- Can set compressor temperature difference on and off.

- Fault alarm (over-temperature alarm, sensor alarm, High pressure alarm, compressor over heat alarm. Delay boot protection, all components grounding safely.

- LED display, display tank temperature and set temperature and can set the over temperature alarm and tank inside temperature, fault prompt functions.

- Non-standard sizes can be customized, Ultra-low temperature freezer(-100℃ tank within 100m3 volume).

- Optional parts: PLC controller, color touch-screen, temperature recorder, etc.

Advantages of Industrial Freezers

Equipment Appearance

Both vertical and horizontal ultra-low temperature refrigerators are available.

At the same time, our equipment can be customized according to customer needs, such as PLC controller, touch screen and temperature recorder recorder.

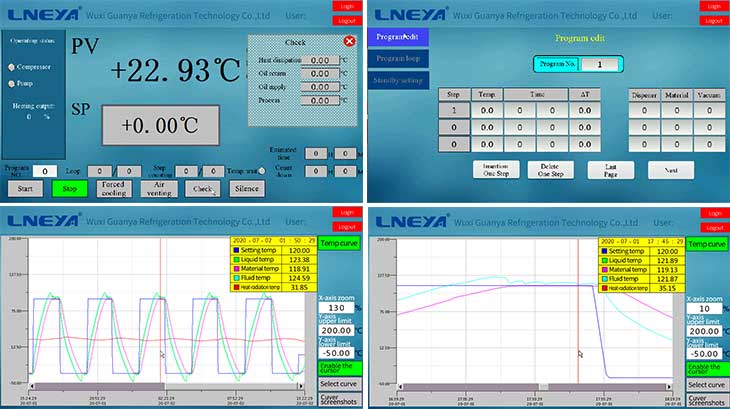

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Applications

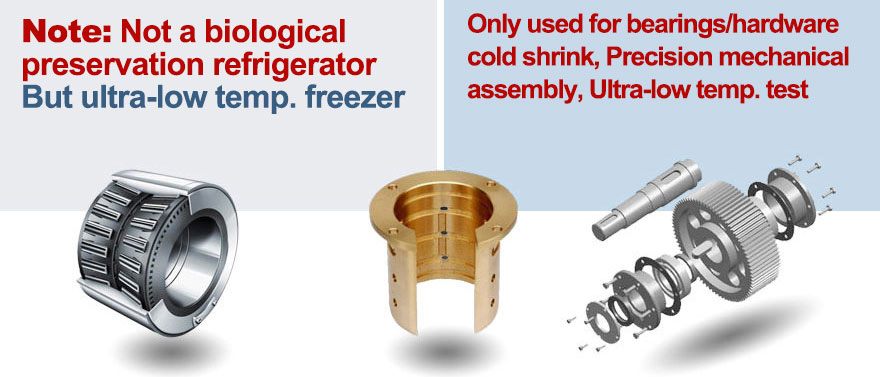

lt is mainly used in industrial refrigerating treatment, so that the matrix of the metal structure to generate a uniform, fine and dispersed precipitation.The precipitation of carbide will improve the abrasion resistance, friction performance and increase hardness of metal.The carbide is the ideal alternative to liquid nitrogen.

Used for the copper sleeve and bearings contracting, it is widely used in precise mechanical assembly. Applied to large scale equipment lower temperature test.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | GX-8028N | GX-8050N | GX-80A10N | GY-8028N | GY-8050N | GY-8080N | GY-80A16N |

| volume | 280L | 500L | 1000L | 280L | 500L | 800L | 1600L |

| Inner dimension | 610*600* 760mm | 800*735* 850mm | 1000*1000* 1000mm | 800*600* 600mm | 1200*650* 650mm | 1350*800* 750mm | 2000*900* 900mm |

| Type | (Vertical) | (Chest/Horizontal) | |||||

| Capacibility carrying | 150KG | 220KG | 300KG | 150KG | 220KG | 300KG | 650KG |

| Designed bearing capacity is two times of the standard one, (refrigeration system is designed according to the standard capacity when target artifact weight is greater than the standard capacity, the cooling rate will decrease) | |||||||

| Temp. range | -80°C~-10°C Optional -80°C~60°C | ||||||

| Cooling capacity at -75℃ | 1kW | 1.5kW | 2.5kW | 1kW | 1.5kW | 2.5kW | 4kW |

| Temp. accuracy | ±2℃ | ±2℃ | ±2℃ | ±2℃ | ±2℃ | ±2℃ | ±2℃ |

| Heating power | 2kW | 3kW | 5kW | 2kW | 3kW | 5kW | 8kW |

| Nickel-chromium alloy electric heating heater, the controller has double safety protection, with independent temperature limiter protection. | |||||||

| Cooling rate | (ambient temperature of 25 degrees, no-load, from 60 degrees to -75 degrees about 1 hour).;cooling rate will be a little different for temperature changes. | ||||||

| Controller | ASET multifunctional controller | ||||||

| Operation panel | 7-inch color touch screen, display set temperature, measured temperature. | ||||||

| Temp. record | Temperature curve and fault record, U-disk data export, excel format. | ||||||

| Inside circulating air | 1650 m³/h | 2100 m³/h | 2750 m³/h | 2100 m³/h | 2750 m³/h | 3500 m³/h | 6000 m³/h |

| When it is open, the internal circulation fan automatically turns off. The touchscreen displays open state. | |||||||

| Compressor | Tecumseh | Dorin | Tecumseh | Dorin | |||

| Intermediate heat exchanger | KAORI Plate heat exchanger | ||||||

| Dry filter | Emerson | ||||||

| Expansion valve | Electronic expansion valve | ||||||

| Evaporator | Copper-tube with aluminum-fin | ||||||

| Cooling Type | Air-cooled with water-cooled auxiliary functions (Ensure good cooling capacity when temp. above 30 degrees) | ||||||

| Means of insulation | Polyurethane foam insulation, thermal insulation layer 125 mm, with embedded FIR boards | ||||||

| Safety Protection | Self-diagnosis function; Phase sequence phase failure protection; leakage protector; cooling unit overload protection; high and low pressure switch, overload relay, thermal protection device, high temperature protection and temperature fault protection. | ||||||

| Case material | Outside is cold rolled steel painting, internal is SUS304 wire drawing board. | ||||||

| Refrigerant | R404A R23 | ||||||

| Dimension | 1150*1150* 1850 | 1350*1300* 1850 | 1550*1500* 2100 | 2200*1150* 1150 | 2700*1200* 1200 | 3200*1300* 1250 | 4000*1400* 1350 |

| Power 380V 50HZ | 7kW MAX | 11.5kW MAX | 15kW MAX | 7kW MAX | 11.5kW MAX | 15kW MAX | 21kW MAX |

| Weight | 400kg | 500kg | 690kg | 415kg | 525kg | 800kg | 1000kg |

| Optional | High temperature reaches 150degree and temperature accuracy is ±0.5degree;the input power will be changed(When select this model, the thickness of thermal insulation layer will be 150mm,thermal insulation material will be silicate and vacuum plate) | ||||||

| Optional | Closed circulating oil heating system, no direct electric heating element inside the box, suitable for flammable products test | ||||||

| Optional | Temp. accuracy ±0.5℃ | ||||||

| Optional | Cooling and heating program controlled, meet cold treatment process requirements(can set 5 programs, each program can edit 45 steps.) | ||||||

| Optional | Interior door, reduce cooling capacity lost when picking small workpieces (temperature below 60 degrees optional) | ||||||

| Optional | Outside SUS304 wire drawing board case | ||||||

| Optional | Diameter 50mm cable hole | ||||||

| Optional | Electric heating vacuum glass observation window (with lighting) 200mm*300mm | ||||||

| Optional | Low temperature automatic defrost (can be once per hour or use manual button to defrost), ensure it can work at low temperature for long time even the door is open and close frequently) | ||||||

Other Products

GX -65 ~ -10°C Industrial Freezers

1045-65 ~ -10°C (optional: -150 ~ -10°C)Temperature Range1 ~ 4kWCooling Capacity5.5 ~ 19kWPower280 ~ 1600LVolume7 / 10 inchColor Touch Screen1650 ~ 6000m³/hInside Circulating Air CUSTOM DESIGN Leave a Message Email Us WhatsApp …

GX -150 ~ -20°C Industrial Cryogenic Freezers

1461-150 ~ -20°C (optional: -150 ~ -10°C)Temperature Range0.7 ~ 2kWCooling Capacity12 ~ 40kWPower280 ~ 1000LVolume7 / 10 inchColor Touch Screen2100 ~ 4500m³/hInside Circulating Air CUSTOM DESIGN Leave a Message Email Us WhatsApp …

GX -100 ~ -30°C Industrial Low Temperature Freezers

1153-100 ~ -30°C (optional: -150 ~ -10°C)Temperature Range0.7 ~ 3kWCooling Capacity9 ~ 30kWPower280 ~ 1600LVolume7 / 10 inchColor Touch Screen1650 ~ 6000m³/hInside Circulating Air CUSTOM DESIGN Leave a Message Email Us WhatsApp …

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller