HRT -45 ~ +250°C Heater Chiller Circulator

Features of Cooling and Heating Circulators

- Wide working temperature range with cooling and heating function.

- With 2pcs of LED display controller, can show the setting temp.&actual value, and alarm value for over temperature.

- Ensure fast cooling at high temperature and can achieve temperature control continuously.

- The cycle system is closed, there is no oil mist and water vapor happened, so as to assure the lab safety and heat transfer fluid lifetime.

- Use Copeland brand compressor, circulation pump, stable performance and reliable quality.

- Self-diagnosis function; freezer overload protection; high pressures witch, overload relay, thermal protection device, liquid low level protection, high temperature protection and temp fault protection.

- Use the same kind of heat conducting in the whole heating-cooling cycle when control heat conducting medium temperature.

- High-lift design and meet the long-distance transportation of heat conducting medium.

Advantages of Cooling and Heating Circulators

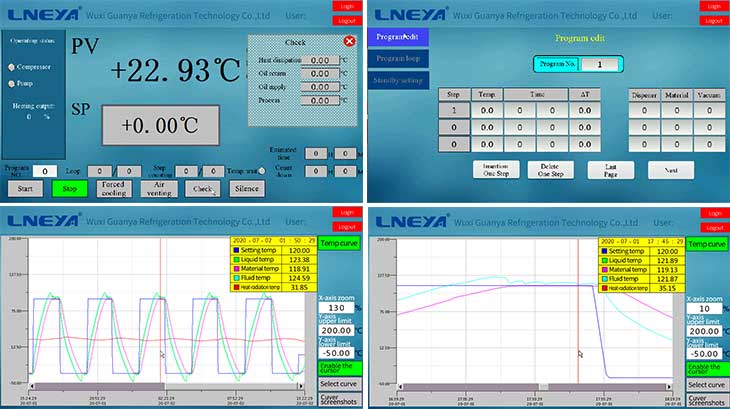

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- The temperature difference between jacket & reactor material can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

- Alarm output

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

Custom Explosion Proof Cabinet

Positive pressure cabinet is composed of positive pressure cavity and control cavity.

Positive pressure cavity is used for installing various of instrument or electronics which with non-explosion-proof.

The control cavity has explosion-proof control box and pressure control system.

The case material of positive pressure cabinet with 2~3mm Cold rolled steel sheet welding and the Air-duct with galvanized steel pipe.

Adopt bulkhead connector and tightening device for in&out of the cable.

There is a glass display in the front of door and display the information of instrument and indicator light.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | HRT-25N | HRT-35N | HRT-50N | HRT-70N | HRT-100N | HRT-150N | |

| Temperature Range | -45℃~250℃ | ||||||

| Controller | PID adaptive controller | ||||||

| Temperature Control | heat-conducting medium outlet temp.control | ||||||

| Temperature Feedback | Heat-conducting medium temperature feedback PT100(measure inlet temperature and outlet temperature) | ||||||

| Temp. Accuracy | ±0.5℃ | ||||||

| Heating Power | 2.5KW | 3.5KW | 5.5KW | 7.5KW | 10KW | 15KW | |

| Cooling Capacity | 250℃ | 2KW | 3.5KW | 5.5KW | 7.5KW | 10KW | 15KW |

| 100℃ | 2KW | 3.5KW | 5KW | 7KW | 10KW | 15KW | |

| 20℃ | 2KW | 3.5KW | 5KW | 7KW | 10KW | 15KW | |

| 0℃ | 1.8KW | 3KW | 5KW | 7KW | 10KW | 15KW | |

| -20℃ | 0.85KW | 1.5KW | 2.8KW | 4.2KW | 6KW | 11KW | |

| -40℃ | 0.25KW | 0.45KW | 0.9W | 1.5KW | 2KW | 3.75KW | |

| Circulation Pump Flow | Max20L/min | Max35L/min | Max35L/min | Max50L/min | Max65L/min | Max110L/min | |

| Circulation Pump Pressure | 1.2BAR | 1.2BAR | 1.2BAR | 1.2BAR | 1.5BAR | 1.5BAR | |

| Compressor | Tecumseh | Emerson copeland | |||||

| Evaporator | Plate heat exchanger | ||||||

| Operation Panel | Display setting temperature and outlet and inlet temperature, 7-inch color touch screen | ||||||

| Data Record | U disk data export, Excel form, error record | ||||||

| Temperature Record | Record setting temperature, outlet and inlet temperature | ||||||

| Safety Protection | Self-diagnosis function; freezer overload protection; high pressure switch; overload relay; thermal protection device and other safety protection. | ||||||

| Closed Circulation System | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supplement oil automatically at low temperature. | ||||||

| Refrigerant | R-404A/R507C | ||||||

| Connection Size | ZG1/2 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | G1 | |

| Dimension(cm) | 40*70*130 | 45*70*160 | 55*70*175 | 55*70*175 | 65*85*185 | 70*85*185 | |

| Weight | 160kg | 185kg | 245kg | 245kg | 320kg | 360kg | |

| Power | AC 220V 50HZ | AC 380V | AC 380V | AC 380V | AC 380V | AC 380V | |

| 4.5kW | 6.2kW | 9kW | 11.5kW | 16kW | 23kW | ||

| Case Material | Cold-rolled sheet spraying (standard color 7035) | ||||||

| Optional | MODBUS RTU Protocl, RS 232 interface | ||||||

| Optional Power | 220V 60HZ three-phase,440V~480V 60HZ three phase | ||||||

Other Products

HR -25 ~ +200°C Refrigerated Heating Circulators

1622-25 ~ +200°C (optional: -45~ +250°C)Temperature Range1 ~ 15kWCooling Capacity4 ~ 21kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen20 ~ 110L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp Fe…

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller