LD -80 ~ -30°C Cryogenic Chillers

Features of Low Temperature Water Chillers

- The ultra-wide temperature control range can meet the temperature requirements of different industries.

- Adopt environmental protection refrigerants.

- Secondary subcooling technology is adopted, with fast refrigeration speed.

- Imported semi closed piston compressor, semi closed piston two-stage compressor and semi closed screw compressor are adopted. The evaporator adopts high force plate heat exchanger, which has small volume and high efficiency.

- A full set of imported cold controls (Danfoss pressure controller, balance valve, expansion valve, solenoid valve, drying filter, Emerson oil separator, alco sight glass, check valve, etc.) are adopted.

- Generator cooling water circuit use intermediate heat exchanger, improve system reliability and safety.

- Danfoss electronic expansion valve is adopted with high control accuracy.

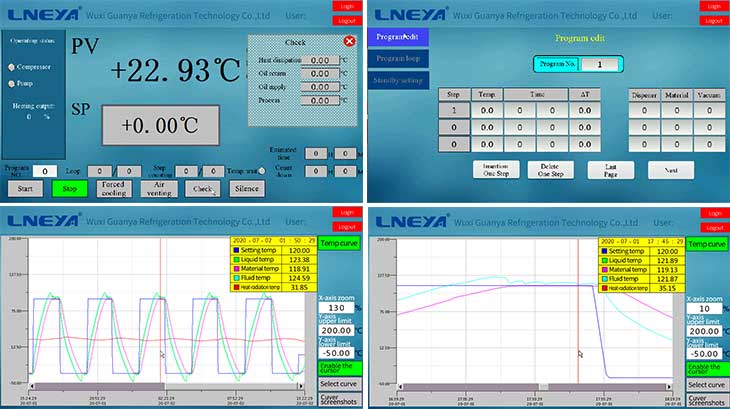

- Siemens PLC S7-200 / 300 controller, LNEYA touch screen display, automatic control and operation, temperature curve display, temperature record can be exported to USB flash disk, fault alarm record and other functions are adopted.

- The large refrigerating capacity equipment adopts semi closed screw compressor with economizer operation, which is combined with electronic expansion valve to ensure high efficiency and energy saving.

- Offer machine installation and system test, users only need to finish the installation of refrigerant and cooling water.

- Factory test: the load test of each equipment in the factory shall not be less than 12 hours.

Advantages of Low Temperature Water Chillers

Refrigeration Principle

The whole working principle process of industrial water chiller can be roughly divided into three parts: water circulation system, refrigeration circulation system and main control system. The water circulation system is also a part that directly reflects the function of the industrial water chiller. It transmits the cold water to the equipment that needs to be cooled, and the cold water absorbs the heat of the equipment and then transmits it back.

The refrigeration cycle system is a process of cooling the cold water that absorbs heat. The refrigerant sublimates and then compresses to bring the heat in the cold water to the outside for dissipation. The main control system is the power control and internal structural components control.

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

- Alarm output

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

Custom Explosion Proof Cabinet

Positive pressure cabinet is composed of positive pressure cavity and control cavity.

Positive pressure cavity is used for installing various of instrument or electronics which with non-explosion-proof.

The control cavity has explosion-proof control box and pressure control system.

The case material of positive pressure cabinet with 2~3mm Cold rolled steel sheet welding and the Air-duct with galvanized steel pipe.

Adopt bulkhead connector and tightening device for in&out of the cable.

There is a glass display in the front of door and display the information of instrument and indicator light.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | LD-4W | LD-6W | LD-8W | LD-12W | LD-20W | LD-30W | LD-40W | LD-60W | LD-90W | LD-120W |

| Temperature Range | -80°C~ -30°C (optional: -150°C ~ -5°C) | |||||||||

| Cooling Capacity At -75°C | 4kw | 6kw | 8kw | 12kw | 20kw | 30kw | 40kw | 60kw | 90kw | 120kw |

| 3440Kcal/h | 5160Kcal/h | 6880Kcal/h | 10320Kcal/h | 17200Kcal/h | 25800Kcal/h | 34400Kcal/h | 51600Kcal/h | 77400Kcal/h | 103200Kcal/h | |

| Circulation Pump Info | 6.6m³/h | 6.6m³/h | 9m³/h | 15m³/h | 25m³/h | 25m³/h | 25m³/h | / | / | / |

| 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | 2.5bar max | / | / | / | |

| Inlet&outlet connection size | DN-25 PN-10 | DN-25 PN-10 | DN-32 PN-10 | DN-40 PN-10 | DN-50 PN-10 | DN-50 PN-10 | DN-50 PN-10 | DN-65 PN-10 | DN-65 PN-10 | DN-80 PN-10 |

| Cooling Water at 30°C | 10m³/h | 14m³/h | 20m³/h | 25m³/h | 35m³/h | 45m³/h | 65m³/h | 90m³/h | 120m³/h | 180m³/h |

| Expansion tank(standard) | 100L | 175L | 250L | 350L | 500L | 600L | 750L | / | / | / |

| Compressor | Dorin compressor/HANBELL/Fusheng/Bitzer screw compressor/Carlyle | Dorin compressor/HANBELL/Fusheng/Bitzer screw compressor/Carlyle | ||||||||

| Evaporator | plate heat exchanger | |||||||||

| Refrigerant | R404A/R23, or R508B | |||||||||

| Secondary refrigerant | Ethanol, dichloromethane, heat transfer oil, etc. | |||||||||

| Safety Protection | High pressure protect; water supply cut-off protection; over-current protection; leakage protection; sequential and phase failure protection; High temperature protection; Sensor Failure protection; Liquid low level protection etc. multi-safety protection | |||||||||

| Level Indicator | Adopt glass liquid level indication | |||||||||

| Piping material | Expansion tank, cold storage tank and circulation pipeline are all made of SUS304 | |||||||||

| Case material | Channel steel + square tube + cold rolled plate sealing plate spray 7035 | |||||||||

| Dimension cm | 100*150*185 | 200*145*205 | 200*145*205 | 250*145*225 | 250*145*225 | 350*160*245 | 400*160*245 | 400*160*245 | 500*200*260 | 650*200*260 |

| Power | 24kW | 27kW | 38kW | 51kW | 69kW | 101kW | 136kW | 200kW | 295kW | 396kW |

| dB | within 75 dB | within 80 dB | within 90 dB | |||||||

| Weight (kg) | 950kg | 1100kg | 1400kg | 1800kg | 2200kg | 3000kg | 3500kg | 4000kg | 5000kg | 6000kg |

| Optional | Optional outside touch screen display controller (separated), the communication line distance is 10 meter | |||||||||

| Optional | Optional explosion-proof touch screen control system (ExdeIIBT4), the communication line distance is 15 meter | |||||||||

Other Products

SLJ -150 ~ -110°C Direct Cooled Chillers

1513-150 ~ -110°C (optional: -150 ~ -5°C)Temperature Range1.4 ~ 11kWCooling Capacity8.6 ~ 36kWPower1.5 ~ 7.8㎡Evaporator Area7 / 10 inchColor Touch Screen2.5 ~ 10m³/hCooling Water CUSTOM DESIGN Leave a Message Email Us WhatsApp …

CDLJ -110 ~ -50°C Ultra Low Temperature Chillers

1543-110 ~ -50°C (optional: -110 ~ -5°C)Temperature Range3 ~ 180kWCooling Capacity @-90℃14 ~ 768kWPower50 ~ 1000LExpansion Tank7 / 10 inchColor Touch Screen6.6 ~ 50m³/hCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsA…

LN -60 ~ -10°C Low Temperature Water Chillers

1493-60 ~ -10°C (optional: -110 ~ -5°C)Temperature Range12 ~ 360kWCooling Capacity @-40℃14 ~ 300kWPower100 ~ 1800LExpansion Tank7 / 10 inchColor Touch Screen6.6 ~ 50m³/hCirculation Pump CUSTOM DESIGN Leave a Message Email Us Whats…

LJ -45 ~ -10°C Low Temperature Refrigeration System

1612-45 ~ -10°C (optional: -110 ~ -5°C)Temperature Range12 ~ 360kWCooling Capacity @-20℃12 ~ 247kWPower50 ~ 1800LExpansion Tank7 / 10 inchColor Touch Screen6.6 ~ 50m³/hCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsA…

loading…

It’s the last post!

LNEYA Chiller

LNEYA Chiller