ZLF -45 ~ +250°C Temperature Control Systems for Multi Reactors

Features of Cooling and Heating Systems

- Previously unachievable performance.

- Intelligent temperature control system.

- Maximum process stability and reproducibility.

- Adop plate heat exchager, Pipeline heating, the fastest heating and cooling rates.

- High cooling power from 0.5 to 1200kW.

- Large temperature range without fluid change.

- Closed system, extend thermal fluid lifetime.

- Incredibly compact.

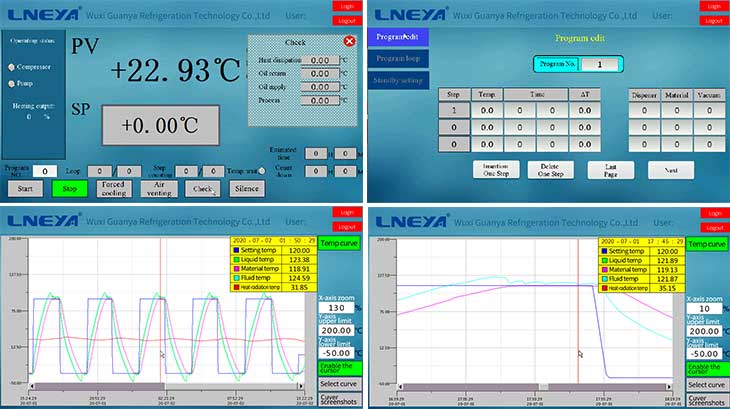

- 7-inch, 10-inch color TFT touch screen display.

- Comprehensive warning and safety functions.

- Rapid cooling down from high temperature.

- Use magnetic drive pump, solve the circulation pump leakage.

Advantages of Cooling and Heating Systems

Structure Design

A fully closed piping design, high efficiency plate heat exchanger used to reduce the demand for the thermal fluid utilization while providing the system to achieve the rapid ups and downs in temperature.

The whole system is a closed liquid circulation system with the expansion of container, expansion of the container and the liquid circulation is adiabatic, and do not participate in liquid circulation, only mechanical connection, regardless of the temperature is a high temperature or low temperature, the tank temperature is limited to 60℃.

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- The temperature difference between jacket & reactor material can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

- Alarm output

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

Configuration Software (Optional)

All dynamic temperature control system can be connected with the computer.

You can install and record the picture of display on the computer via the configuration software.

- Communication distance less than 200m.

- Easily temperature setting.

- Real time control screen.

- Curve records.

- Program selection.

- Alarm screen recording.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | ZLF-35N ZLF-35NS ZLF-35NH ZLF-35NSH | ZLF-50N ZLF-50NS ZLF-50NH ZLF-50NSH | ZLF-80N ZLF-80NS ZLF-80NH ZLF-80NSH | ZLF-125N ZLF-125NS ZLF-125NH ZLF-125NSH | ZLF-200N ZLF-200NS ZLF-200NH ZLF-200NSH |

| Temp. range ℃ | -45~ 250°C (setting the max temp according to the supplier heating or cooling source) -40~135°C(The maximum temperature range can be operated by using glycol water formula.) | ||||

| ZLF- N | The main cold source/or main heat source is used to regulate the flow of the system through proportional regulation system, and control the heat of the clamping of the reaction tank, and a set of heat exchanger for heating or cooling is controlled or cooled. | ||||

| ZLF- NS | Besides ZLF- N function,add one set heater used to reduce high temp. | ||||

| ZLF- NH | Besides ZLF- N function,add electrical heating function | ||||

| ZLF- NSH | Besides ZLF- N function,add one set heater used to reduce high temp and electrical heating function | ||||

| Heat exchanger area | 3.5m2 | 5m2 | 8m2 | 12.5m2 | 20m2 |

| Electric heating function H | 25KW | 35KW | 50KW | 65KW | 80KW |

| With “H” has heating function | |||||

| Control mode | Feed forward PID + Our special dynamic control calculation,LNEYA PLC controller | ||||

| Communication protocol | MODBUS RTU protocol,RS485 interface,optional Ethernet interface/R232 interface | ||||

| Temp control selection | Reactor material temperature control | ||||

| Temperature feedback | The temperature of three points: the inlet and outlet of heat-conducting medium, material in reactor(External temperature sensor), PT100 sensor | ||||

| Process temp. feedback | Raw material process feedback:PT100 or 4~20mA or communication given Temp. feedback:PT100 | ||||

| temp feedback: normal PT100 | |||||

| Temperature accuracy | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ |

| Circulation pump | 150L/min 2.5BAR | 200L/min 2.5BAR | 400L/min 2.5BAR | 500L/min 2.5BAR | 750L/min 2.5BAR |

| Input and display | 7-inch color touch screen,temperature graph display | ||||

| Safety protection | Self-diagnosis function;freezer overload protection;high pressure switch;overload relay;thermal protection device;liquid low level protection;high temp. Protection and temp. fault protection. | ||||

| Perform valve piece | Electric proportional control valve, control signal 4~20mA. | ||||

| Piping material | SUS304 | ||||

| Connection size | DN40 | DN40 | DN-50 | DN-65 | DN-80 |

| Dimension cm | 150*120*185 | 180*120*210 | 180*120*210 | 225*120*240 | 225*120*240 |

| Power AC380V50HZ | 2.3kw(max) | 3.5kw(max) | 4.5kw(max) | 8kw(max) | 10.5kw(max) |

| With H power AC380V 50HZ | 27.3kw(max) | 38.5kw(max) | 54.5kw(max) | 73kw(max) | 90.5kw(max) |

| Case material | Cold-rolled sheet spraying (standard color 7035) | ||||

LNEYA Chiller

LNEYA Chiller