KRY -40 ~ +100°C Battery Cooling System

Features of Vehicle Test Chillers

- Multi channel output, independent control of flow, no interference with each other.

- Temperature, flow and pressure can be controlled separately.

- Multi channel temperature control, and one device can achieve multi channel output, and control the flow separately.

- Strong circulation pump ensures the delivery of high viscosity liquid, it can provide high flow under stable pressure.

- Clear circuit, compact structure, multiple fault alarm functions to ensure safe operation of the equipment.

- Temperature variation range is usually from -40 to 100 degrees (which can be extended to 150 degrees). While controlling the temperature, you can also choose to control the flow or pressure.

- Equipped with powerful circulating pump to ensure the delivery of high viscosity liquid; Variable frequency regulation or proportional regulation valve is used to control the flow output to achieve high-precision control of 5% ~ 100% of the total range.

- The temperature control equipment can be flexibly connected with other test platforms.

Advantages of Vehicle Test Chillers

Multi Channel Temperature Control

KRY series automotive test chillers support multiple channel temperature control

- Independent flow and pressure control

- temperature, flow and pressure are controlled independently.

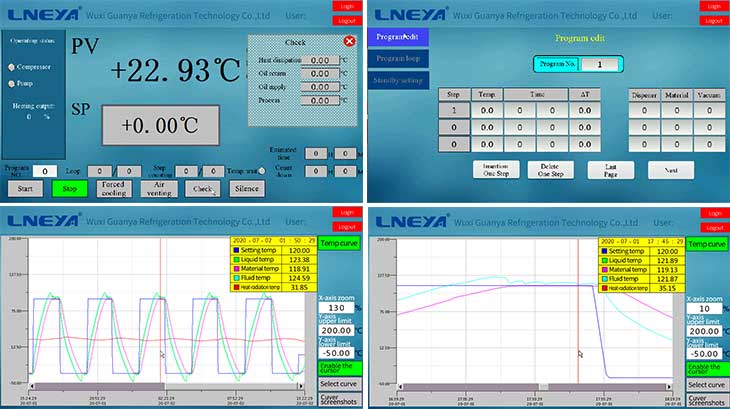

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- The temperature difference between jacket & reactor material can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

Vehicle Performance Test

The new energy vehicle component test unit is mainly used for the offline detection of the drive motor of the new energy vehicle according to relevant test stanards and requuirements, it can test and simulate the performance requirements of motor in actual vehicle operation.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | KRY-455 | KRY-475 | KRY-4A10 | KRY-4A15 | KRY-4A25 | KRY-4A38W | KRY-4A60W | |

| KRY-455W | KRY-475W | KRY-4A10W | KRY-4A15W | KRY-4A25W | ||||

| Temp Range | -40℃~+100℃ | |||||||

| Temperature control precision | ±0.5℃ | |||||||

| Temperature feedback | Pt100 | |||||||

| Temperature display | 0.01k | |||||||

| Flow rate output | 1~20 L/min | 1~25 L/min | 1~25 L/min | 1~40 L/min | 1~40 L/min | 1~40 L/min | 1~40 L/min | |

| Flow description | / | When the temp. is below -30℃, | When the temp. is below-30℃, | |||||

| the maximum flow rate is 25L/min. | the maximum flow rate is 30L/min. | |||||||

| Flow rate accuracy | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2 L/min | ±0.2L/min | |

| Pressure display | Adopt the Jeffron pressure sensor, the touch screen display the pressure, can carry on the pressure control adjustment. | |||||||

| Heating power | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| Cooling Capacity | 100℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW |

| 20℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| 0℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| -20℃ | 2.8kW | 4.5kW | 6kW | 10kW | 16kW | 25kW | 35kW | |

| -35℃ | 1.2kW | 1.8kW | 2.5kW | 4kW | 6.5kW | 10kW | 15kW | |

| Compression | Emerson Valley Wheel Compressor | |||||||

| Expansion valve/solenoid valve | Electronic expansion valve | |||||||

| Oil distributor | Emerson | |||||||

| Dry filter, Pressure control | Danfoss | |||||||

| Evaporator | plate heat exchanger | |||||||

| Input,Display | Siemens 7-inch color touch screen \ Siemens s7-1200 PLC controller | |||||||

| Program edit | 10 procedures may be prepared, each of which may be composed of 40 steps | |||||||

| Communication | CAN communication bus | |||||||

| Safety protection | Self-diagnosis function; freezer overload protection; high pressure pressure switch, overload relay, thermal protection device, low liquid level protection, high temperature protection, sensor fault protection, etc. | |||||||

| Closed circulation | The whole system is a fully enclosed system. There is no oil mist at high temperature, and low temperature does not absorb moisture in the air. The system does not increase the pressure due to high temperature during operation, and the heat medium is automatically replenished at low temperature. | |||||||

| system | ||||||||

| refrigerant | R404A/ R507C | |||||||

| Connection size | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | |

| Cooling water@25C | 1900L/H | 2500L/H | 3000L/H | 4000L/H | 6000L/H | 9000L/H | 15000L/H | |

| Condenser(W) | Tube type heat exchanger (Paris/Shenshi) | |||||||

| Condenser(A) | Copper tube aluminum finned heat exchanger (upward wind) | |||||||

| Power 380V50HZ | 10kW max | 14kW max | 17kW max | 25kW max | 38kW max | 58kW max | 84kW max | |

| Dimension cm | 55*100*175 | 55*100*175 | 70*100*175 | 80*120*185 | 100*150*185 | 100*150*185 | 200*145*205 | |

| Weight (water cooling) | 250kg | 280kg | 320kg | 360kg | 620kg | 890kg | 1300kg | |

| Optional | 220V 60HZ Three phase 400V 50HZ Three phase 440V 60HZ Three phase | |||||||

| Optional | Extend to -40~+135℃ | |||||||

| Optional | Higher precision control of temperature, flow and pressure | |||||||

| Optional | Automatic antifreeze filling system | |||||||

| Optional | Automatic antifreeze filling system | |||||||

Other Products

CNYL-5 Energy Storage Battery Chiller

1581±0.5℃Temperature Accuracy5 ~ 8.5kWCooling CapacityR410ARefrigerant7 inchTouch Screen-45℃ ~ +55℃Ambient Operating Temperature CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Energy Storage Battery Chill…

ZLJ Direct Cooling Heating Systems

1531Air CooledCooling Type5 ~ 10kWCooling CapacityR134ARefrigerant380V 50HZPower SupplyPLC ControllerControl System CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Direct Cooling Heating Systems The a…

KRY 0 ~ +100°C 1&3 Car Battery Cooler

13740 ~ +100°C (optional: -40 ~ +100°C)Temperature Range11 ~ 60kWCooling Capacity22 ~ 68kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen3200 ~ 15000L/HCooling Water CUSTOM DESIGN Leave a Message Email Us WhatsApp Fe…

KRY -40 ~ +100°C 1&6 Lithium Ion Battery Cooling System

1066-40 ~ +100°CTemperature Range5 ~ 60kWCooling Capacity38 ~ 82kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen8000 ~ 18000L/HCooling Water CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Vehicle Test C…

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller