WTD -45 ~ +250°C Cooling Heating System for Microchannel Reactors

Features of Cooling and Heating Systems

- It is specially designed and developed for the characteristics of small liquid holding capacity, strong heat exchange capacity, and large pressure drop in the circulation system of the microchannel reactor.

- Optimize temperature sampling and response speed, specially design control algorithm, can respond quickly to stable temperature control.

- Enhance the design of the circulating pump capacity to meet the high pressure drop requirements of the reactor.

- Continuous high temperature cooling technology to meet the requirement of stable operation when the temperature control is required for high temperature exothermic reaction.

Advantages of Cooling and Heating Systems

Structure Design

A fully closed piping design, high efficiency plate heat exchanger used to reduce the demand for the thermal fluid utilization while providing the system to achieve the rapid ups and downs in temperature.

The whole system is a closed liquid circulation system with the expansion of container, expansion of the container and the liquid circulation is adiabatic, and do not participate in liquid circulation, only mechanical connection, regardless of the temperature is a high temperature or low temperature, the tank temperature is limited to 60℃.

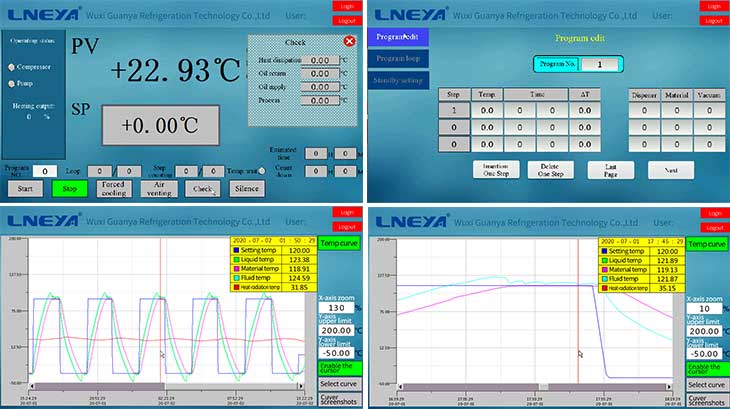

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- The temperature difference between jacket & reactor material can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

Configuration Software (Optional)

All dynamic temperature control system can be connected with the computer.

You can install and record the picture of display on the computer via the configuration software.

- Communication distance less than 200m.

- Easily temperature setting.

- Real time control screen.

- Curve records.

- Program selection.

- Alarm screen recording.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | WTD-255-2T Dual temperature zone | WTD-455-2T Dual temperature zone | |||

| Temperature range | -25°C~200°C | -45°C~250°C | |||

| Temperature control accuracy | ±0.3℃ | ±0.3℃ | |||

| Temperature resolution | 0.1K | 0.1K | |||

| Operation panel | 7 inch color touch screen | 7 inch color touch screen | |||

| Data curve | Data curve record | Data curve record | |||

| Data output | U disk excel format | U disk excel format | |||

| Control mode | Fuzzy PID adaptive controller | Fuzzy PID adaptive controller | |||

| Heating power | 5.5kw | 5.5kw | 5.5kw | 5.5kw | |

| Refrigeration ability | 250°C | 5.5kw | 5.5kw | ||

| 100°C | 5.5kw | 5.5kw | 5.5kw | 5.5kw | |

| 100°C | 5kw | 5kw | 5 kw | 5kw | |

| 20°C | 5kw | 5kw | 5 kw | 5kw | |

| -20°C | 2 kw | 2 kw | 4 kw | 4kw | |

| -35°C | 1.5kw | 1.5kw | |||

| Circulating pump max | 25L/min 3bar Two way | 25L/min 3bar Two way | |||

| Connection size | R3/4 Two way | R3/4 Two way | |||

| Temperature Sensor | PT100 | PT100 | |||

| Display 2 sets of inlet and outlet liquid temperature | Display 2 sets of inlet and outlet liquid temperature | ||||

| Compressor | Emerson Copeland | Emerson Copeland | |||

| Evaporator | Plate Heat Exchanger | Plate Heat Exchanger | |||

| Cooling method | Air cooling + water cooling | Air cooling + water cooling | |||

| Expansion valve | Electronic expansion valve | Electronic expansion valve | |||

| Filter drier | Danfoss | Danfoss | |||

| Refrigerant | R404A | R404A | |||

| Pipe material | SUS304 | SUS304 | |||

| Ultra-high temperature cooling technology | Yes | Yes | |||

| Metal insulation hose | 1.8M*4 root | 1.8M*4 root | |||

| Contactor\Circuit Breaker | Schneider | Schneider | |||

| Size cm | 70*100*175 | 70*100*175 | |||

| Weight | 325KG | 365KG | |||

| Power supply | 380V 50HZ 17KW MAX | 380V 50HZ 19KW MAX | |||

Other Products

WTD -70 ~ +300°C Cooler Heater

1233-70 ~ +300°C (optional: -150 ~ +350°C)Temperature Range1.1 ~ 7.5kWCooling Capacity2 ~ 7.5kWHeating Power±0.3°CAccuracy7 / 10 inchColor Touch Screen7 ~ 25L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp …

WTD -70 ~ +200°C Cooling Heating System

1330-70 ~ +200°C (optional: -150 ~ +350°C)Temperature Range11 ~ 50kWCooling Capacity38 ~ 50kWHeating Power±0.5°CAccuracy7 / 10 inchColor Touch Screen250L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp …

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller