KRY-O +5 ~ +135°C Oil Chiller Systems

Features of Oil Chiller Systems

- Multi channel output, independent control of flow, no interference with each other.

- Temperature, flow and pressure can be controlled separately.

- Multi channel temperature control, and one device can achieve multi channel output, and control the flow separately.

- Strong circulation pump ensures the delivery of high viscosity liquid, it can provide high flow under stable pressure.

- Clear circuit, compact structure, multiple fault alarm functions to ensure safe operation of the equipment.

- Temperature variation range is usually from -40 to 100 degrees (which can be extended to 150 degrees). While controlling the temperature, you can also choose to control the flow or pressure.

- Equipped with powerful circulating pump to ensure the delivery of high viscosity liquid; Variable frequency regulation or proportional regulation valve is used to control the flow output to achieve high-precision control of 5% ~ 100% of the total range.

- The temperature control equipment can be flexibly connected with other test platforms.

Advantages of Oil Chiller Systems

Multi Channel Temperature Control

KRY series automotive test chillers support multiple channel temperature control

- Independent flow and pressure control

- temperature, flow and pressure are controlled independently.

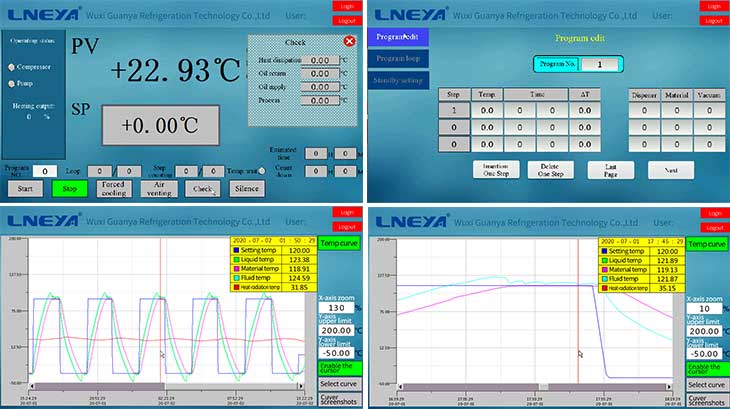

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- The temperature difference between jacket & reactor material can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

Vehicle Performance Test

The new energy vehicle component test unit is mainly used for the offline detection of the drive motor of the new energy vehicle according to relevant test stanards and requuirements, it can test and simulate the performance requirements of motor in actual vehicle operation.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | KRY-OA15W | KRY-OA25W | KRY-OA38W | KRY-OA15W2S | KRY-OA25W2S | KRY-OA38W2S | |

| Temperature Range | +5℃~+135℃ | ||||||

| Accuracy | ±0.3℃ | ||||||

| Feedback | PT100 | ||||||

| Flow | 2L/min~20L/min One in one out, in and out control linkage | 2L/min~15L/min Two outputs, one input, flow control linkage | |||||

| Flow Accuracy | ±0.2L/min | ||||||

| Pressure | 0.2bar~2.5bar | ||||||

| Heating Capacity | 15KW | 25KW | 38KW | 15KW | 25KW | 38KW | |

| Cooling Capacity | 125℃ | 15kw | 25kw | 38kw | 15kw | 25kw | 38kw |

| 20℃ | 15kw | 25kw | 38kw | 15kw | 25kw | 38kw | |

| Compressor | Emerson Copeland Scroll Flexible Compressor / Japanese Scroll Flexible Compressor | ||||||

| Throttling Device | Electronic expansion valve | ||||||

| Evaporator | Plate heat exchanger | ||||||

| Circulation Pump | gear pump | ||||||

| Flow Regulation | Inverter vector regulation | ||||||

| Input And Display | 7-inch color touch screen \ PLC controller | ||||||

| Communication | CAN communication bus | ||||||

| Refrigerant | R410A | ||||||

| Secondary Refrigerant | Oil | ||||||

| Cooling Water 20°C | 4000L/H | 4000L/H | 6000L/H | 8500L/H | 4000L/H | 6000L/H | |

| Cooling Water Interface | ZG1 | ZG1 | ZG1 1/8 | ZG1 | ZG1 | ZG1 1/8 | |

| Power Supply | 380V 50HZ Three-phase five-wire system | ||||||

| Circuit Breaker | 63A | 80A | 125A | 63A | 80A | 125A | |

| External Tooling | External oil return tool size 600×850×600 When the external oil return tool is selected, the tool needs to be installed under the test motor | ||||||

Other Products

KRYCH -40 ~ +100°C Automotive Battery Test Chamber Chiller

1316-40 ~ +100°C (or custom)Temperature Range4 ~ 15kWCooling CapacityR125/R507C/R404ARefrigerant±0.5°CAccuracy7 / 10 inchColor Touch Screen25m³/HCooling Water CUSTOM DESIGN Leave a Message Email Us WhatsApp Features o…

KRY 0 ~ +100°C 1&2 Battery Discharge Test

15530 ~ +100°C (optional: -40 ~ +100°C)Temperature Range1.8*2 ~ 60*2kWCooling Capacity9 ~ 120kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen5600 ~ 24000L/HCooling Water CUSTOM DESIGN Leave a Message Email Us WhatsApp …

ZLJ Direct Cooling Heating Systems

1531Air CooledCooling Type5 ~ 10kWCooling CapacityR134ARefrigerant380V 50HZPower SupplyPLC ControllerControl System CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Direct Cooling Heating Systems The a…

KRY -40 ~ +100°C 1&2 Fuel Cell Cooling System

1333-40 ~ +100°CTemperature Range1.8*2 ~ 60*2kWCooling Capacity30 ~ 158kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen4000 ~ 30000L/HCooling Water CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Vehicle…

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller