AI -105 ~ +125°C Recirculating Air Temperature Control System

Features of Recirculating Air Temperature Control System

- It is widely used in high and low temperature testing of semiconductor equipment. Cold and heat sources for high temperature and low temperature constant temperature test of electronic equipment;

- Independent refrigeration cycle fan unit;

- It can work continuously for a long time and defrost automatically. The defrosting process does not affect the storage temperature;

- Modular design, easy replacement of standby unit (if there are 10 units, only one standby unit can be used);

- Solve the problem of frequent door opening and closing and frosting of evaporation system; The defrosting process of the evaporation system has no influence.

- It is simple to build a set of high and low temperature constant temperature chamber transformer (according to the drawings provided, the box shall be spliced like building blocks, the electricity and water shall be connected, and the work can be started after the temperature is set).

Advantages of Recirculating Air Temperature Control System

Working Principle

It is used to cool the gas (non corrosive) or recover it as non corrosive gas by condensation and liquefaction.

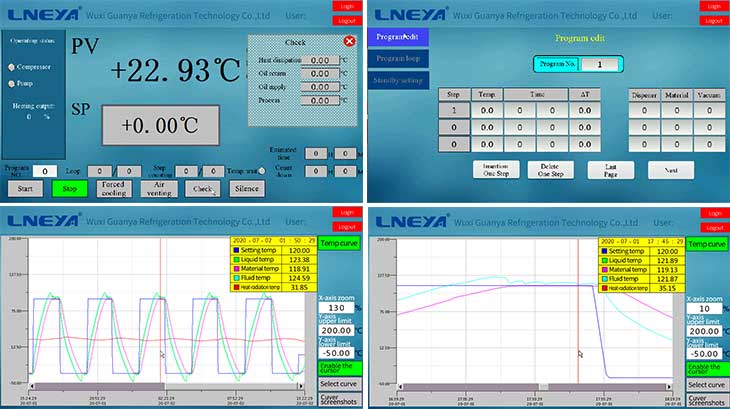

Display Function

- Display all the kind of process control temperatures.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Typical Applications

It is used to cool the gas (without corrosion): normal temperature gases such as dry compressed air, nitrogen and argon are introduced into LQ series equipment, and the gas can reach the target low temperature and be supplied to the components or heat exchangers for demand test.

Used for automotive sensors, vehicle control products, electronic control units or ECUs, incoming parts inspection, semiconductor IC verification, simuation-based tesing, cooling heating stress full cycle, desgin or fabrication weakness, fast hot&cold thermal cycling, electronic and mechanical subsystems, core module chip test, auxiliary module chip test, MCU chip test, microcontroller Unit chip test.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | AI-635/635W | AI-835W | AI-1055W | |

| Temperature range | -65℃~125℃ | -85℃~125℃ | -105℃~125℃ | |

| Control mode | PID Adaptive controller | |||

| Communication protocol | RS485 Interface,Modbus RTU Protocol | |||

| Temperature feedback | PT100 | |||

| Operation panel | 7-inch color touch screen controller, temperature curve record, data export to EXCEL format. | |||

| Temp. accuracy | ±0.2℃ | |||

| Heating power | 3.5kW | 3.5kW | 3.5kW | |

| Cooling capacity | 125℃ | 3.5kW | 3.5kW | 3.5kW |

| 50℃ | 3.5kW | 3.5kW | 3.5kW | |

| 20℃ | 3.5kW | 3.5kW | 3.5kW | |

| 0℃ | 3.5kW | 3.5kW | 3.5kW | |

| -20℃ | 3kW | 3.5kW | 3.5kW | |

| -40℃ | 2.1kW | 2.5kW | 3.5kW | |

| -60℃ | 1kW | 2.1kW | 3kW | |

| -75℃ | 1kW | 2kW | ||

| -95℃ | 1kW | |||

| Circulating air flow | 550m3/h | 550m3/h | 550m3/h | |

| Compressor | Emerson | |||

| Safety protection | Self-diagnosis function;freezer overload protection;high pressure switch,overload relay,thermal protection device,liquid low level protection,high temp. protection and temp. fault protection | |||

| Defrosting device | There are installed defrosting device and condensate drain inside | |||

| Timing on&off operation | Can set a key time for starting up & stop | |||

| Refrigerant | R404A R23 | R404A R508B | R404A R23 R14 | |

| Water-cooled type (cooling water at 20℃) | 1200L/H | 1600L/H | 2600L/H | |

| 1.5bar~4bar | 1.5bar~4bar | 1.5bar~4bar | ||

| Dimension (cm) | 55*100*175 | 55*100*175 | 70*100*175 | |

| Weight | 280kg | 300kg | 360kg | |

| Power | AC 380V 50HZ | AC380V50HZ | AC380V50HZ | |

| 7kW | 7.3kW | 9.5kW | ||

| Optional | High Temperature -65℃ ~ 165℃, -85℃ ~ 165℃ | |||

Other Products

LQ -110 ~ -40°C Gas Cooler

1477-110 ~ -40°CTemperature Range15 ~ 100m³/hAir Flow Rate1.2 ~ 11.5kWPower0.8 ~ 13㎡Heat Exchanger Area7 / 10 inchColor Touch Screen CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Gas Cooler Gas heat…

AES -115 ~ +225°C Temperature Forcing Systems

1467-115 ~ +225°CTemperature Range10 ~ 30m³/hAir Handling Capacity3.7 ~ 7.5kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen0.6 ~ 3m³Cooling Water CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Temperatu…

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller