SUNDI -25 ~ +300°C Cooling Heating Systems

Features of Cooling and Heating Systems

- Previously unachievable performance.

- Intelligent temperature control system.

- Maximum process stability and reproducibility.

- Adop plate heat exchager, Pipeline heating, the fastest heating and cooling rates.

- High cooling power from 0.5 to 1200kW.

- Large temperature range without fluid change.

- Closed system, extend thermal fluid lifetime.

- Incredibly compact.

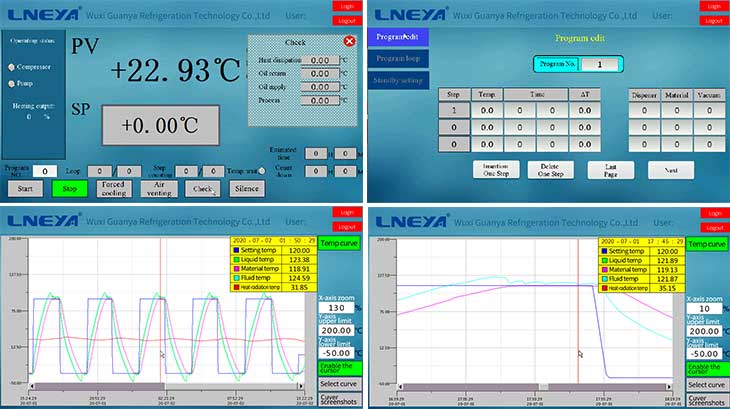

- 7-inch, 10-inch color TFT touch screen display.

- Comprehensive warning and safety functions.

- Rapid cooling down from high temperature.

- Use magnetic drive pump, solve the circulation pump leakage.

Advantages of Cooling and Heating Systems

Structure Design

A fully closed piping design, high efficiency plate heat exchanger used to reduce the demand for the thermal fluid utilization while providing the system to achieve the rapid ups and downs in temperature.

The whole system is a closed liquid circulation system with the expansion of container, expansion of the container and the liquid circulation is adiabatic, and do not participate in liquid circulation, only mechanical connection, regardless of the temperature is a high temperature or low temperature, the tank temperature is limited to 60℃.

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- The temperature difference between jacket & reactor material can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

- Alarm output

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

Configuration Software (Optional)

All dynamic temperature control system can be connected with the computer.

You can install and record the picture of display on the computer via the configuration software.

- Communication distance less than 200m.

- Easily temperature setting.

- Real time control screen.

- Curve records.

- Program selection.

- Alarm screen recording.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | SUNDI-225V SUNDI-225WV | SUNDI-235V SUNDI-235WV | SUNDI-255V SUNDI-255WV | SUNDI-275V SUNDI-275WV | SUNDI-2A10V SUNDI-2A10WV | SUNDI-2A15V SUNDI-2A15WV | SUNDI-2A25V SUNDI-2A25WV | SUNDI-2A38WV | SUNDI-2A60WV | SUNDI-2A95WV | |

| Temp. range | -25℃~+300℃ | ||||||||||

| Control Mode | Feedback PID + Our special dynamic control calculation, PLC controller | ||||||||||

| Temp. control | Process temp. control and jacket temp. control model | ||||||||||

| Temp. difference | Set or control the temperature difference between jacket oil and raw material process | ||||||||||

| Program Editor | 10 programs, each program can edit 40 steps. | ||||||||||

| Communication Portocol | MODBUS RTU Protocol, RS485 interface | ||||||||||

| Material temp. feedback | PT100 OR 4~20mA or communication(normal: PT100) | ||||||||||

| Temp. feedback | The temp. of three points: the inlet and outlet of equipment, reactor material temp.(external temp. sensor) | ||||||||||

| Medium temp. acccuracy | ±0.5℃ | ±0.5℃ | |||||||||

| Material temp. accuracy | ±1℃ | ||||||||||

| Heating power kW | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 | |

| Cooling capacity kW at | 300℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 |

| 20℃ | 2.5 | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 | |

| -5℃ | 2 | 3 | 4.5 | 6.6 | 8 | 12 | 19 | 30 | 46 | 70 | |

| -20℃ | 1 | 1.8 | 2.8 | 3.8 | 4.6 | 7 | 12 | 16 | 22 | 32 | |

| Circulation pump max L/min bar | 20 | 35 | 35 | 50 | 60 | 110 | 150 | 150 | 250 | 400 | |

| 1.2 | 1.2 | 1.2 | 1.2 | 1.5 | 1.5 | 1.5 | 1.5 | 2.5 | 2.5 | ||

| Pump | Magnetic drive pump | Magnetic drive pump | |||||||||

| Compressor | Tecumseh | Emerson copeland/scroll compressor | Emerson copeland/Carlyle | ||||||||

| Expansion valve | Electronic expansion valve | ||||||||||

| Evaporator | Plate heat exchanger | ||||||||||

| Operation Panel | 7-inch touch screen,show temp curve\EXCEL data output | ||||||||||

| Safety protection | Self-diagnosis function; freezer overload protection; high pressure switch, overload relay,thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. | ||||||||||

| Closed circulation system | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. | ||||||||||

| Refrigerant | R404A/R507C | ||||||||||

| Connection size | ZG1/2 | ZG3/4 | ZG3/4 | ZG1 | ZG1 | ZG1 | DN32 PN10 | DN40 PN10 | DN50 PN10 | DN65 PN10 | |

| Water-cooled type W(cooling water@20℃) | 600L/H 1.5bar~4bar | 800L/H 1.5bar~4bar | 1200L/H 1.5bar~4bar | 1600L/H 1.5bar~4bar | 2400L/H 1.5bar~4bar | 3000L/H 1.5bar~4bar | 6m³/H 1.5bar~4bar | 10m³/H 1.5bar~4bar | 12m³/H 1.5bar~4bar | 18m³/H 1.5bar~4bar | |

| Dimension cm | 40*70*130 | 45*70*160 | 55*70*175 | 55*70*175 | 65*85*185 | 70*85*185 | 80*120*185 | 100*150*185 | 200*145*205 | 200*145*205 | |

| Weight kg | 130 | 180 | 195 | 260 | 320 | 390 | 620 | 820 | 1100 | 1350 | |

| Power 380V 50HZ | 4kW | 6kW | 8kW | 11kW | 14kW | 21kW | 35kW | 54kW | 81kW | 126kW | |

| Case material | Cold-rolled sheet spraying (standard color 7035) | ||||||||||

| Optional | Optional Ethernet interface, configure the computer operating software. Optional outside touch screen display controller(separated),the communication line distance is 10 meter. | ||||||||||

| Optional | The heating power is within 25KW, and the SUNDI series can be equipped with an optional temperature control accuracy of ±0.1°C. | ||||||||||

Other Products

SUNDI -10 ~ +200°C Cooling Heating Systems

-10 ~ +150°C (optional: -150 ~ +350°C)Temperature Range1.5 ~ 15kWCooling Capacity3.6 ~ 20kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen20 ~ 75L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp …

SUNDI -45 ~ +250°C Heater Chillers

-45 ~ +250°C (optional: -150 ~ +350°C)Temperature Range0.45 ~ 200kWCooling Capacity6.5 ~ 280kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen35 ~ 600L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp …

SUNDI -90 ~ +250°C Heater and Cooler in One

-90 ~ +250°C (optional: -150 ~ +350°C)Temperature Range0.2 ~ 80kWCooling Capacity8 ~ 170kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen20 ~ 400L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp …

SUNDI -70 ~ +250°C Cooler and Heater

-70 ~ +250°C (optional: -150 ~ +350°C)Temperature Range0.4 ~ 15kWCooling Capacity5.2 ~ 28kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen20 ~ 110L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp …

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller