UC +50 ~ +200°C Heaters

Features of Heating Systems

- Equipped with heating cooling container, with large heat transfer area, fast heat-up and cool-down, small heat transfer oil demand.

- Can heat-up and cool-down continuously.

- The whole cycle is full closed,there is no oil mist at high temperature, heat transfer oil can not be oxidized and browning.

- With function of internal PT100 for correcting internal circulation.

- The whole system is closed with expansion tank, the expansion tank and liquid circulation are thermal insulation, do not participate in liquid circulation, regardless of high or low temperature, the medium in expansion tank is limited to 60℃.

Advantages of Heating Systems

Custom Explosion Proof Cabinet

Positive pressure cabinet is composed of positive pressure cavity and control cavity.

Positive pressure cavity is used for installing various of instrument or electronics which with non-explosion-proof.

The control cavity has explosion-proof control box and pressure control system.

The case material of positive pressure cabinet with 2~3mm Cold rolled steel sheet welding and the Air-duct with galvanized steel pipe.

Adopt bulkhead connector and tightening device for in&out of the cable.

There is a glass display in the front of door and display the information of instrument and indicator light.

Display Function

- Display all the kind of process control temperatures.

- Shows the liquid level of the heat conducting medium in the expansion vessel.

- Shows indication for refrigeration system working.

- Shows indication for heater working.

- Shows indication for circulation pump working.

- Display the temperature control.

- The temperature upper limit, lower limit control can be set.

- The temperature difference between jacket & reactor material can be set.

- Shows the alarm to add the liquid when it is empty.

- The refrigeration compressor can be set to operate manually or automatically.

Data Interface and Software

Standard configuration:

- PT100 temperature sensor input interface.

- USB export data interface.

- RS485 communication interface (MODBUS protocol).

- Alarm output

Optional:

- 4 ~ 20mA Input interface for temperature measurement.

- 4 ~ 20mA Input interface for setting temperature.

- Ethernet interface.

- RS232 communication interface (MODBUS protocol).

- Profibus-DP interface.

- Computer operation software (optional Ethernet interface).

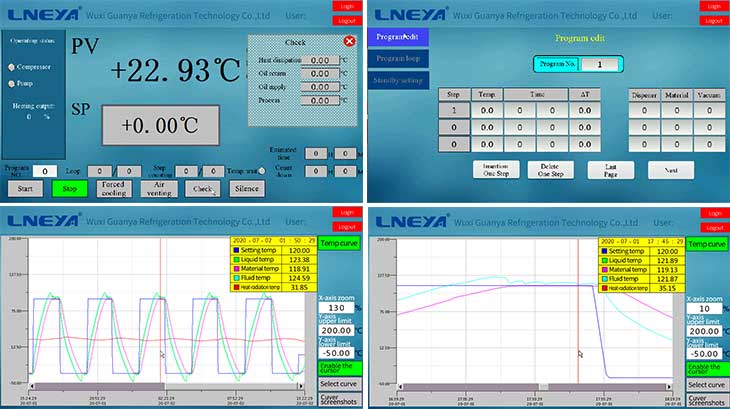

Configuration Software (Optional)

All dynamic temperature control system can be connected with the computer.

You can install and record the picture of display on the computer via the configuration software.

- Communication distance less than 200m.

- Easily temperature setting.

- Real time control screen.

- Curve records.

- Program selection.

- Alarm screen recording.

Products Parameters

Noted: Can provide customized services all types of equipment. Please consult us for details.

| Model | LY-5020 | LY-A020 | UC-5020 | UC-A1020 | UC-A1520 | |

| Medium temperature range | +50℃~+170℃ | |||||

| Temperature control | Fuzzy PID Adaptive Controller | |||||

| Temperature control options | Heat transfer medium outlet temperature control | |||||

| Temperature feedback | Heat transfer medium temperature feedback PT100 | |||||

| Temperature Control Accuracy | ±0.5℃ | |||||

| Heating power | 5.5kW | 10kW | 5.5kW | 10kW | 15kW | |

| Cooling capacity | 170℃ | 5.5kW | 10kW | 15kW | ||

| 100℃ | 4kW | 8kW | 12kW | |||

| 65℃ | 1.8kW | 3.4kW | 5kW | |||

| Circulation pump flow, pressure Max | 35L/min 1.5BAR | 50L/min 1.5BAR | 35L/min 1.5BAR | 50L/min 1.5BAR | 50L/min 1.5BAR | |

| Heater | Flange pipe electric heater | |||||

| Independent temperature limiter | Rainbow Temperature Protector | |||||

| Cooler | Copper Tube Aluminum Fin Air Cooled Condenser | |||||

| Operation panel | Display the set temperature and measured temperature, key operation input temperature | |||||

| Security | Various safety protection functions such as overload relay and thermal protection device. | |||||

| Closed circulation system | The whole system is a fully closed system, there will be no oil mist at high temperature, and no moisture in the air will be absorbed at low temperature, the system will not increase the pressure due to high temperature during operation, and the heat transfer medium will be automatically replenished at low temperature. | |||||

| Connection size | ZG3/4 | ZG3/4 | ZG3/4 | ZG3/4 | ZG1 | |

| Dimensions cm | 40*70*130 | 40*70*130 | 40*70*130 | 40*70*130 | 70*100*175 | |

| Weight | 70kg | 80kg | 78kg | 128kg | 170kg | |

Power max AC 380V 50HZ | 5.9kW | 10.8kW | 6kW | 10.9kW | 15.7kW | |

| shell material | Plastic spraying of cold-rolled sheet (standard color 7035) | |||||

| Optional | Optional 7-inch color touch screen, record temperature curve, data export in excel format | |||||

| Optional | SUS304 shell | |||||

| Optional | Optional external touch screen controller, communication line distance 10m | |||||

| Optional | Optional explosion-proof touch screen control system (ExdeIIBT4), communication line distance 15m | |||||

| Optional power supply | 220V 60HZ three-phase, 440V~480V 60HZ three-phase | |||||

Other Products

UC +50 ~ +300°C Heating Machines

1450+50 ~ +300°CTemperature Range3.5 ~ 200kWHeating Power5 ~ 212kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen35 ~ 600L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Heating Syste…

ST series RT+10 ~ +135°C Hot Water Heating Machine

1097RT+10 ~ +135°CTemperature Range25 ~ 300kWHeating Power1.8 ~ 7.5kWPower±1°CAccuracy7 / 10 inchColor Touch Screen110 ~ 600L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Heating Sys…

UST +50 ~ +300°C Heating Circulators

1285RT+10 ~ +300°CTemperature Range3.5 ~ 95kWHeating Power5 ~ 101kWPower±0.5°CAccuracy7 / 10 inchColor Touch Screen35 ~ 400L/minCirculation Pump CUSTOM DESIGN Leave a Message Email Us WhatsApp Features of Heating Syst…

loading…

已经是到最后一篇内容了!

LNEYA Chiller

LNEYA Chiller